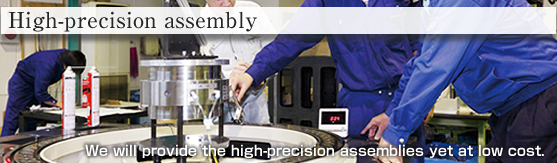

Cost-down, yet high-precision

Our company's strength is to provide high-precision assemblies at low cost.

This is possible because we perform both parts processing and assembling simultaneously in our factories.

Other than eliminating man-hour for manufacturing and intermediate-margin, we devise methods for parts-processing which is conducted before assembling.

It will be our pleasure to contribute our techniques and knowledge to help grant your requests.

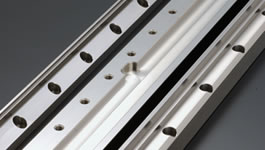

Devise method for parts-processing is important for high-precision assembly

With the most common way to perform parts-processing, precision is produced only within the parts themselves.However, when it comes to parts assemblies, no matter how much the parts are precisely processed in advance, small errors might appear at the end of the assembling process.

"Providing the right precision in assembling" is important to perform the precision overall.

Parts are will be assembled at the end, and are designed to be assembled . Therefore, it is true that assembly and adjustment are as important as processing the part itself. Understanding this is the key to enable high-precision processing.

We believe that providing high-precision for each parts is not necessarily more important than performing precision assembling.

Devising a method to improve parts-processing is the key to process high-precision assembling.

Murakami Seiki�fs Precision Machining

| Cutting process | |

| EDM (Electric Discharge Machining) | |

| Grinding process | |

Preventing the over performance during processing

With our techniques of 50 years, we perform machining while understanding precision, functions, and strength for each parts at different processes.

By understanding well where to adjust in assembling and which part needs a closer attention in processing, an over-performance and duplicate precision measurements are avoidable.

To improve the quality of the product; Possible proposal for a change in materials

In order to understand the precision, strength and functionalities etc. of each different parts, we have to understand the same for the materials as well. When processing the assembling parts, we may find a way to lower the cost while maintain their functionalities by replacing the assigned materials to more suitable ones. This is possible when we are well acquainted about materials themselves.

We will provide proposals for the arrangement with a good understanding based on a plan for your reasons and purposes to use the assigned materials.

We can supply necessary materials for the machining as well.

We will provide every possible proposals in order to make our transaction profitable for both you and our company.

Complete testing system will ensure the precision of the assemblies

Talyvel

The electronic spirit level to measure plane degree

Autocollimator

For measuring straightness and parallelism degree

Kisage technique for scraping improve precision

When assembling the precisely-processed machine parts, margins of errors are avoidable even if we process each individual parts precisely. The finished products may even have a big errors after assembling.

It is impossible to polish assembled parts with machineries, however, with Kisage technique for scraping, it is possible to reduce final errors even after assembling.

It is also possible to enhance precision by having parts rub against each other and reducing the error.

Murakami Seiki's Ultra-precision Machining

Murakami Seiki was established in 1948 as a specialist group of ultra-precision machining and assembling. Ever since our foundation, we have engaged in ultra-precision parts manufacturing and put efforts to improve the precision of machine tools and measurement instruments.

With 50 years of our technical expertise, we have been gaining liabilities as an expert of ultra-precision machining. Feel free to contact us especially about ultra-precision machining and assembling.